- Benefits of Laser Cleaning for Brick Surfaces

- Techniques Used in Laser Cleaning for Brick Surfaces

- Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Brick Surfaces

- Case Studies of Successful Laser Cleaning Projects on Brick Surfaces

- Safety Precautions for Laser Cleaning on Brick Surfaces

Benefits of Laser Cleaning for Brick Surfaces

| Benefit | Description |

|---|---|

| Non-abrasive | Laser cleaning is a non-abrasive method, meaning it does not damage the surface of the brick. Traditional cleaning methods, such as sandblasting or chemical cleaning, can wear down the surface of the brick over time. Laser cleaning is gentle yet effective, preserving the integrity of the brick. |

| Precision | Laser cleaning allows for precise control over the cleaning process. The laser beam can be adjusted to target specific areas or stains on the brick surface, ensuring a thorough and even clean. This precision helps to avoid over-cleaning or damaging the brick. |

| No chemicals | Unlike traditional cleaning methods that rely on harsh chemicals, laser cleaning is a chemical-free process. This makes it an environmentally friendly option for cleaning brick surfaces, as it does not release harmful substances into the air or water supply. |

| Efficiency | Laser cleaning is a fast and efficient method of cleaning brick surfaces. The high-powered laser beam can quickly remove dirt, grime, and other contaminants without the need for extensive scrubbing or rinsing. This saves time and labor costs compared to traditional cleaning methods. |

| Safe | Laser cleaning is a safe method for cleaning brick surfaces. Unlike some traditional cleaning methods that can pose health risks to workers, such as exposure to harmful chemicals or dust, laser cleaning is a safe and controlled process. It also eliminates the need for manual labor, reducing the risk of injuries. |

In conclusion, laser cleaning offers several benefits for cleaning brick surfaces. It is a non-abrasive, precise, chemical-free, efficient, and safe method of removing dirt and grime from brick surfaces. This modern technology provides a gentle yet effective cleaning solution that preserves the integrity of the brick while saving time and labor costs. Consider using laser cleaning for your next brick surface cleaning project to experience these benefits firsthand.

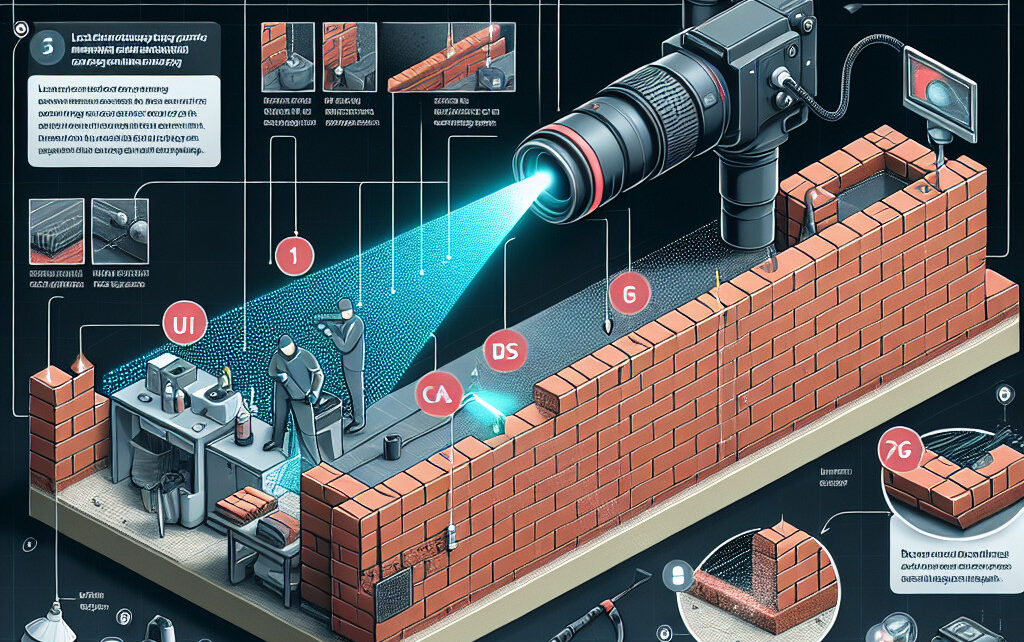

Techniques Used in Laser Cleaning for Brick Surfaces

Brick surfaces are a common feature in many buildings, both old and new. Over time, these surfaces can become dirty and stained, detracting from the overall appearance of the building. Traditional cleaning methods such as pressure washing or chemical cleaning can be effective, but they can also be harsh on the brick and may not always remove all stains. Laser cleaning is a relatively new technique that is gaining popularity for cleaning brick surfaces. In this article, we will explore the .

How Does Laser Cleaning Work?

Laser cleaning works by using a high-powered laser beam to remove contaminants from the surface of the brick. The laser beam is directed at the surface, where it heats up and vaporizes the contaminants, leaving behind a clean surface. The process is non-abrasive and does not damage the brick, making it an ideal choice for cleaning delicate surfaces.

Types of Lasers Used

There are several types of lasers that can be used for cleaning brick surfaces, including:

1. CO2 Lasers: These lasers are commonly used for cleaning brick surfaces. They have a high power output and can effectively remove contaminants without damaging the brick.

2. YAG Lasers: YAG lasers are another popular choice for cleaning brick surfaces. They are versatile and can be used for a wide range of cleaning applications.

3. Fiber Lasers: Fiber lasers are a newer technology that is becoming increasingly popular for cleaning brick surfaces. They are highly efficient and can provide precise cleaning results.

Techniques Used in Laser Cleaning

There are several techniques that can be used in laser cleaning for brick surfaces, including:

1. Spot Cleaning: This technique involves directing the laser beam at specific spots on the brick surface to remove stains or contaminants. It is a precise method that can target problem areas without affecting the surrounding brick.

2. Line Cleaning: In this technique, the laser beam is moved in a linear pattern across the brick surface to remove contaminants. It is a more efficient method for cleaning larger areas of brick.

3. Surface Cleaning: Surface cleaning involves directing the laser beam at the entire surface of the brick to remove contaminants. This technique is ideal for cleaning large areas of brick quickly and effectively.

Benefits of Laser Cleaning

There are several benefits to using laser cleaning for brick surfaces, including:

1. Non-abrasive: Laser cleaning is a non-abrasive method that does not damage the brick surface.

2. Environmentally Friendly: Laser cleaning does not require the use of harsh chemicals, making it an environmentally friendly cleaning option.

3. Efficient: Laser cleaning is a fast and efficient method for cleaning brick surfaces, saving time and labor costs.

4. Precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the contaminants are removed without affecting the brick surface.

In conclusion, laser cleaning is a highly effective and efficient method for cleaning brick surfaces. By using high-powered lasers and various techniques, contaminants can be removed from brick surfaces without damaging the underlying material. This environmentally friendly and precise cleaning method is becoming increasingly popular for restoring the appearance of brick buildings.

Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Brick Surfaces

Brick surfaces are a common feature in many buildings, both old and new. Over time, these surfaces can become dirty and stained, detracting from the overall appearance of the building. In order to maintain the aesthetic appeal of brick surfaces, it is important to regularly clean them. There are two main methods for cleaning brick surfaces: traditional cleaning methods and laser cleaning. In this article, we will compare these two methods and discuss their advantages and disadvantages.

Traditional Cleaning Methods

Traditional cleaning methods for brick surfaces typically involve the use of water, detergent, and scrubbing brushes. This method is effective at removing dirt, grime, and stains from brick surfaces, but it can be time-consuming and labor-intensive. Additionally, traditional cleaning methods can be harsh on the brick surface, potentially causing damage or erosion over time.

Some common traditional cleaning methods for brick surfaces include:

– Pressure washing: This method involves using a high-pressure water spray to remove dirt and grime from the surface of the bricks. While pressure washing can be effective at cleaning brick surfaces, it can also cause damage if not done properly.

– Chemical cleaning: Chemical cleaners are often used to break down tough stains and grime on brick surfaces. However, these cleaners can be harsh and may damage the bricks if not used correctly.

– Manual scrubbing: This method involves using a scrubbing brush or sponge to manually scrub the surface of the bricks. While effective, manual scrubbing can be time-consuming and labor-intensive.

Laser Cleaning

Laser cleaning is a relatively new method for cleaning brick surfaces that involves the use of a laser beam to remove dirt, grime, and stains. This method is highly effective at cleaning brick surfaces without causing damage or erosion. Laser cleaning is also faster and more efficient than traditional cleaning methods, making it a popular choice for many building owners.

Some advantages of laser cleaning for brick surfaces include:

– Precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the dirt and grime are removed without damaging the bricks.

– Efficiency: Laser cleaning is a fast and efficient method for cleaning brick surfaces, saving time and labor costs.

– Environmentally friendly: Laser cleaning does not require the use of harsh chemicals, making it a more environmentally friendly option compared to traditional cleaning methods.

– Safety: Laser cleaning is a safe method for cleaning brick surfaces, as it does not involve the use of harmful chemicals or abrasive materials.

Comparison

When comparing laser cleaning to traditional cleaning methods for brick surfaces, there are several factors to consider. While traditional cleaning methods can be effective at removing dirt and grime, they can also be time-consuming, labor-intensive, and potentially damaging to the bricks. Laser cleaning, on the other hand, offers a faster, more efficient, and safer alternative for cleaning brick surfaces.

In conclusion, laser cleaning is a superior method for cleaning brick surfaces compared to traditional cleaning methods. It offers precision, efficiency, environmental friendliness, and safety, making it the ideal choice for maintaining the aesthetic appeal of brick surfaces. Building owners should consider using laser cleaning for their brick surfaces to ensure they remain clean and well-maintained for years to come.

Case Studies of Successful Laser Cleaning Projects on Brick Surfaces

Brick surfaces are a common feature in many buildings, both old and new. Over time, these surfaces can become dirty and stained, detracting from the overall appearance of the structure. Traditional cleaning methods such as pressure washing or chemical cleaning can be effective, but they can also be harsh on the brick and may not always produce the desired results.

In recent years, laser cleaning has emerged as a highly effective and environmentally friendly alternative for cleaning brick surfaces. By using a laser beam to remove dirt, grime, and other contaminants from the surface of the brick, laser cleaning can restore the original appearance of the brick without causing damage.

Here are some :

1. Historic Building Restoration 🏛️

One of the most common applications of laser cleaning on brick surfaces is in the restoration of historic buildings. These buildings often have intricate brickwork that can be difficult to clean using traditional methods. In one case study, a team of restoration experts used laser cleaning to remove years of dirt and grime from the exterior of a historic building, revealing the original beauty of the brickwork underneath.

2. Commercial Building Maintenance 🏢

In another case study, a commercial building owner used laser cleaning to maintain the appearance of their brick facade. Over time, the brick had become discolored and stained, making the building look unkempt. By using laser cleaning, the owner was able to quickly and effectively remove the stains and restore the brick to its original color, improving the overall appearance of the building.

3. Public Space Cleaning 🌳

Laser cleaning has also been used in public spaces to clean brick surfaces such as sidewalks, plazas, and retaining walls. In one case study, a city government used laser cleaning to remove graffiti and other stains from a brick retaining wall in a public park. The process was quick and efficient, allowing the city to maintain the cleanliness of the park without causing damage to the brick surface.

4. Residential Brick Cleaning 🏡

Homeowners have also benefited from laser cleaning on brick surfaces. In one case study, a homeowner used laser cleaning to remove years of dirt and grime from the exterior of their home. The process was non-invasive and environmentally friendly, making it a popular choice for homeowners looking to improve the appearance of their property.

In conclusion, laser cleaning has proven to be a highly effective and versatile method for cleaning brick surfaces. Whether it’s restoring a historic building, maintaining a commercial property, cleaning a public space, or improving the appearance of a residential property, laser cleaning offers a safe and efficient solution for removing dirt, grime, and stains from brick surfaces. With its ability to restore the original beauty of brick without causing damage, laser cleaning is sure to continue to be a popular choice for cleaning projects in the future. Try it out for yourself and see the amazing results!

Safety Precautions for Laser Cleaning on Brick Surfaces

1. Wear Protective Gear

When using a laser for cleaning purposes, it is important to wear the appropriate protective gear to protect yourself from potential hazards. This includes wearing safety goggles to protect your eyes from the laser beam, as well as gloves and a long-sleeved shirt to protect your skin from potential burns.

2. Ensure Proper Ventilation

Laser cleaning can produce fumes and smoke that may be harmful if inhaled. It is important to ensure that the area where the cleaning is taking place is well-ventilated to prevent the buildup of harmful fumes. If necessary, use a ventilation system or wear a respirator to protect yourself from inhaling harmful substances.

3. Keep a Safe Distance

When using a laser for cleaning purposes, it is important to maintain a safe distance from the surface being cleaned to prevent accidental burns or injuries. Make sure to follow the manufacturer’s guidelines for the recommended distance between the laser and the surface being cleaned.

4. Avoid Reflective Surfaces

When using a laser for cleaning purposes, it is important to avoid reflective surfaces that may bounce the laser beam back towards you. This can cause serious injuries or damage to your eyes or skin. Make sure to position yourself in a way that minimizes the risk of the laser beam being reflected back towards you.

5. Follow Proper Operating Procedures

Before using a laser for cleaning purposes, make sure to familiarize yourself with the proper operating procedures and safety guidelines provided by the manufacturer. This will help ensure that the cleaning process is carried out safely and effectively.

6. Monitor the Cleaning Process

While using a laser for cleaning purposes, it is important to monitor the cleaning process closely to ensure that it is being carried out effectively. Make sure to adjust the settings as needed to achieve the desired results without causing damage to the brick surface.

7. Have a First Aid Kit on Hand

In case of any accidents or injuries during the laser cleaning process, it is important to have a first aid kit on hand to provide immediate medical attention. Make sure to familiarize yourself with the contents of the first aid kit and how to use them in case of an emergency.

By following these safety precautions, you can ensure that the laser cleaning process is carried out safely and effectively on brick surfaces. Remember to always prioritize safety and take the necessary precautions to protect yourself and others from potential hazards.

- Sure! Here are some questions related to Software employee time tracking for small businesses: - 10 November 2025

- Sure! Here are some questions in English related to the topic The most popular mobile application programming languages: - 15 October 2025

- Sure! Here are some questions related to the hiring process at a software development company: - 6 October 2025