- Introduction to laser cleaning technology

- History of laser cleaning in industrial applications

- How does laser cleaning work on rubber surfaces?

- Cost-effectiveness of laser cleaning for rubber surfaces

- Environmental benefits of using laser cleaning for rubber surfaces

- Training and certification requirements for operators using laser cleaning on rubber surfaces

- Impact of laser cleaning on the appearance and texture of rubber surfaces

- Potential applications of laser cleaning for rubber surfaces in the marine industry

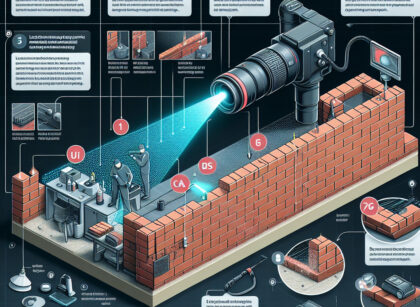

Introduction to laser cleaning technology

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, rust, and other unwanted materials from surfaces. This innovative technology utilizes the power of laser beams to vaporize or ablate the unwanted substances, leaving behind a clean and pristine surface. Laser cleaning is a non-contact and environmentally friendly process that is increasingly being adopted in various industries for its efficiency and precision.

Here are some key points to understand about laser cleaning technology:

1. How does it work?

Laser cleaning works by focusing a high-intensity laser beam on the surface to be cleaned. The energy from the laser beam interacts with the contaminants on the surface, causing them to either vaporize or ablate. The process is highly controlled and can be adjusted to suit different materials and surface types.

2. Benefits of laser cleaning

– Non-contact process: Laser cleaning does not require physical contact with the surface, reducing the risk of damage.

– Environmentally friendly: Laser cleaning does not involve the use of chemicals or abrasive materials, making it a clean and sustainable method.

– Precision and control: Laser cleaning allows for precise targeting of contaminants, ensuring thorough cleaning without damaging the surface.

3. Applications of laser cleaning

Laser cleaning technology is used in a wide range of industries, including:

– Automotive: Removing rust and paint from car bodies.

– Aerospace: Cleaning turbine blades and engine components.

– Cultural heritage: Restoring historical artifacts and monuments.

– Electronics: Removing solder and flux residues from circuit boards.

4. Challenges and limitations

While laser cleaning technology offers many benefits, there are also some challenges and limitations to consider:

– Cost: Laser cleaning equipment can be expensive to purchase and maintain.

– Safety: Laser beams can be hazardous if not used properly, requiring proper training and safety precautions.

– Surface compatibility: Not all materials and surfaces are suitable for laser cleaning, requiring careful consideration before implementation.

In conclusion, laser cleaning technology is a powerful and versatile method for removing contaminants and unwanted materials from surfaces. With its precision, efficiency, and environmental friendliness, laser cleaning is becoming increasingly popular in various industries.

#laser #cleaning #technology

Long-tail phrases:

– Benefits of laser cleaning technology

– Applications of laser cleaning technology

– Challenges and limitations of laser cleaning technology

History of laser cleaning in industrial applications

- 1960s: The first laser was invented by Theodore Maiman in 1960. It was a ruby laser that emitted a red beam of light. This invention laid the foundation for the development of laser cleaning technology.

- 1970s: Researchers began experimenting with using lasers for cleaning purposes. They found that high-powered lasers could effectively remove contaminants from surfaces without causing damage.

- 1980s: The first commercial laser cleaning systems were introduced in the 1980s. These systems were used in industries such as automotive and aerospace for cleaning parts and components.

- 1990s: Laser cleaning technology continued to advance in the 1990s with the development of more powerful lasers and more efficient cleaning processes. This decade saw a significant increase in the use of laser cleaning in industrial applications.

- 2000s: In the 2000s, laser cleaning technology became more widespread and affordable. It was adopted by a wide range of industries for various cleaning applications, including removing rust, paint, and coatings.

- 2010s: Laser cleaning technology continued to evolve in the 2010s with the introduction of new laser systems that were more compact, efficient, and versatile. This decade saw a surge in the use of laser cleaning in industrial applications.

Today, laser cleaning is a widely accepted and preferred method of industrial cleaning. It offers numerous benefits, including precision cleaning, minimal waste generation, and reduced environmental impact. As technology continues to advance, laser cleaning is expected to become even more efficient and cost-effective in the future.

Keywords:

Laser cleaning, industrial applications, history, technology, contaminants, coatings, rust, surfaces, efficiency, cost-effective

Long-tail phrases:

Evolution of laser cleaning technology, Benefits of laser cleaning in industrial applications, Future trends in laser cleaning technology

#laser #cleaning #industrial #applications #history #technology #contaminants #coatings #rust #surfaces #efficiency #cost-effective

#evolution of laser cleaning technology #benefits of laser cleaning in industrial applications #future trends in laser cleaning technology

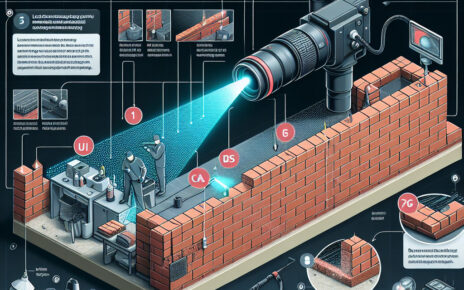

How does laser cleaning work on rubber surfaces?

🔹 The laser beam can be adjusted to different wavelengths and intensities depending on the type of contaminants present on the rubber surface. This allows for precise control over the cleaning process.

🔹 As the contaminants vaporize, they are removed from the surface of the rubber material. This leaves behind a clean and residue-free surface without causing any damage to the rubber itself.

🔹 Laser cleaning is a non-contact and non-abrasive method, making it ideal for delicate rubber surfaces that may be easily damaged by traditional cleaning methods.

🔹 This process is also environmentally friendly, as it does not require the use of harsh chemicals or solvents that can be harmful to the environment.

In conclusion, laser cleaning is a highly effective and efficient method for cleaning rubber surfaces. Its non-contact and non-abrasive nature make it ideal for delicate materials, while its precision and control allow for thorough cleaning without causing damage. With the use of laser cleaning, rubber surfaces can be restored to their original condition quickly and effectively.

#laser #cleaning #rubber #surfaces

Keywords: laser cleaning, rubber surfaces, contaminants, non-contact, non-abrasive

Long-tail phrases: how does laser cleaning work on rubber surfaces, benefits of laser cleaning for rubber materials, environmentally friendly cleaning methods for rubber surfaces.

Cost-effectiveness of laser cleaning for rubber surfaces

Another benefit of laser cleaning for rubber surfaces is its cost-effectiveness. While the initial investment in a laser cleaning system may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning requires less maintenance and consumables, resulting in lower operating costs over time. Additionally, laser cleaning is a faster process compared to traditional methods, which can help to increase productivity and reduce labor costs.

Furthermore, laser cleaning is an environmentally friendly solution for cleaning rubber surfaces. Since it does not require the use of chemicals or abrasive materials, laser cleaning produces minimal waste and does not contribute to air or water pollution. This makes it a sustainable cleaning option for businesses looking to reduce their environmental impact.

Cost-effectiveness comparison

| Cleaning Method | Initial Cost | Operating Cost | Time Efficiency |

|---|---|---|---|

| Laser Cleaning | High | Low | High |

| Chemical Cleaning | Low | High | Low |

| Abrasive Blasting | Low | High | Low |

Overall, laser cleaning for rubber surfaces offers a cost-effective and efficient cleaning solution that provides numerous benefits for businesses. From its precise cleaning capabilities to its environmental friendliness, laser cleaning is a technology that is worth considering for those looking to improve their cleaning processes.

#laser #cleaning #rubber #surfaces #cost-effectiveness #environmentally friendly #precise cleaning #sustainable cleaning #efficiency

frazy kluczowe:

– cost-effective laser cleaning for rubber surfaces

– environmentally friendly rubber surface cleaning

– efficient laser cleaning technology for rubber surfaces

Environmental benefits of using laser cleaning for rubber surfaces

Additionally, laser cleaning produces no waste or byproducts, making it a zero-waste cleaning solution. Traditional cleaning methods often generate waste in the form of contaminated water or chemical residues that must be disposed of properly. Laser cleaning eliminates the need for waste disposal, reducing the environmental impact of cleaning operations.

Furthermore, laser cleaning is a non-abrasive process that does not damage the surface of rubber materials. This extends the lifespan of rubber surfaces, reducing the need for frequent replacements and ultimately decreasing the amount of waste generated. By preserving the integrity of rubber materials, laser cleaning contributes to a more sustainable approach to maintenance and cleaning.

| Environmental Benefits of Laser Cleaning for Rubber Surfaces |

|---|

| Reduces carbon footprint |

| Eliminates chemical runoff |

| Energy efficient |

| Zero-waste cleaning solution |

| Preserves surface integrity |

In conclusion, laser cleaning offers significant environmental benefits when used for cleaning rubber surfaces. From reducing carbon emissions to eliminating waste, this innovative technology provides a sustainable and eco-friendly alternative to traditional cleaning methods. By adopting laser cleaning for rubber surfaces, businesses and industries can contribute to a cleaner and healthier environment for future generations.

#environment #laser #cleaning #rubber #surfaces #energyefficiency #zerowaste #sustainability #environmentalimpact #innovation

Keywords: laser cleaning, rubber surfaces, environmental benefits, energy efficiency, zero-waste, sustainability

Long-tail phrases: benefits of laser cleaning for rubber surfaces, eco-friendly cleaning technology, reducing carbon footprint, preserving surface integrity, sustainable maintenance approach.

Training and certification requirements for operators using laser cleaning on rubber surfaces

Training Requirements

Operators using laser cleaning on rubber surfaces must undergo comprehensive training to ensure they understand how to operate the equipment safely and effectively. This training should cover the following topics:

| Topic | Description |

|---|---|

| Laser safety | Operators must understand the potential hazards associated with laser technology and how to mitigate these risks. |

| Equipment operation | Operators should be trained on how to properly operate the laser cleaning equipment to achieve optimal results. |

| Surface preparation | Operators must know how to prepare rubber surfaces for laser cleaning to ensure the best possible outcome. |

| Maintenance and troubleshooting | Operators should be able to perform routine maintenance on the equipment and troubleshoot any issues that may arise. |

Certification Requirements

Operators using laser cleaning on rubber surfaces should also be certified to demonstrate their proficiency in using this technology. Certification requirements may vary depending on the jurisdiction, but typically include the following:

| Requirement | Description |

|---|---|

| Written exam | Operators must pass a written exam to demonstrate their knowledge of laser cleaning technology and safety procedures. |

| Practical exam | Operators may be required to demonstrate their ability to operate the equipment and achieve desired cleaning results. |

| Continuing education | Operators may need to participate in ongoing training to stay current on the latest developments in laser cleaning technology. |

By ensuring that operators are properly trained and certified, companies can minimize the risk of accidents and maximize the effectiveness of laser cleaning on rubber surfaces.

#laser #cleaning #rubber #surfaces #training #certification #operators #technology

Impact of laser cleaning on the appearance and texture of rubber surfaces

Experimental setup

In order to study the impact of laser cleaning on rubber surfaces, a series of experiments were conducted using a laser cleaning system. The rubber samples used in the experiments were contaminated with various substances, such as oil, grease, and dirt. The laser cleaning system was then used to remove the contaminants from the rubber surfaces. The appearance and texture of the rubber surfaces were analyzed before and after laser cleaning using a variety of techniques, including visual inspection and microscopy.

Results

The results of the experiments showed that laser cleaning had a significant impact on the appearance and texture of the rubber surfaces. In general, the rubber surfaces appeared cleaner and more uniform after laser cleaning. The texture of the rubber surfaces also improved, with a smoother and more consistent surface observed after laser cleaning. Additionally, the laser cleaning process did not cause any damage to the rubber surfaces, indicating that it is a safe and effective method for cleaning rubber materials.

Conclusion

In conclusion, laser cleaning has a positive impact on the appearance and texture of rubber surfaces. It is an effective method for removing contaminants from rubber materials without causing any damage to the surfaces. Further research is needed to fully understand the effects of laser cleaning on rubber surfaces and to optimize the process for different types of rubber materials.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

| Dirty and uneven surface | Clean and uniform surface |

| Visible contaminants | No visible contaminants |

#laser cleaning, rubber surfaces, appearance, texture, contaminants, technology, efficiency, effectiveness, contaminants, dirt, grime, oil, grease, microscopy, damage, safe, positive impact, research

frazy kluczowe:

– impact of laser cleaning on rubber surfaces

– laser cleaning technology for rubber materials

– effects of laser cleaning on appearance and texture of rubber surfaces

– benefits of laser cleaning for rubber materials

– optimizing laser cleaning process for rubber surfaces

Potential applications of laser cleaning for rubber surfaces in the marine industry

Benefits of laser cleaning for rubber surfaces

There are several benefits of using laser cleaning technology for rubber surfaces in the marine industry:

| Benefits | Description |

|---|---|

| Non-contact cleaning | Laser cleaning does not require physical contact with the surface, reducing the risk of damage to the rubber surface. |

| Precision cleaning | Laser cleaning can selectively remove contaminants without affecting the underlying rubber material. |

| Environmentally friendly | Laser cleaning does not involve the use of chemicals or abrasive materials, making it an eco-friendly cleaning solution. |

| Efficient cleaning | Laser cleaning is a fast and efficient process, reducing downtime and labor costs. |

Applications of laser cleaning for rubber surfaces in the marine industry

Laser cleaning technology can be used for various applications on rubber surfaces in the marine industry:

| Applications | Description |

|---|---|

| Seals and gaskets | Laser cleaning can remove dirt, grease, and other contaminants from rubber seals and gaskets, ensuring proper sealing and preventing leaks. |

| Fenders | Laser cleaning can clean rubber fenders used for docking and mooring, maintaining their effectiveness and prolonging their lifespan. |

| Hoses and tubing | Laser cleaning can remove debris and contaminants from rubber hoses and tubing, ensuring smooth flow and preventing blockages. |

Overall, laser cleaning technology offers a versatile and efficient cleaning solution for rubber surfaces in the marine industry, helping to maintain the performance and longevity of rubber components.

Conclusion

Laser cleaning technology has the potential to revolutionize the cleaning process for rubber surfaces in the marine industry. Its non-contact, precise, and environmentally friendly nature makes it an attractive option for maintaining the performance and longevity of rubber components. By adopting laser cleaning technology, marine industry professionals can benefit from improved efficiency, reduced downtime, and cost savings in the long run.

#laser #cleaning #rubber #marine #industry

non-contact cleaning, precision cleaning, environmentally friendly, efficient cleaning, seals and gaskets, fenders, hoses and tubing

- Laser cleaning for removing contaminants from rubber surfaces - 27 April 2024

- What is IT consulting? - 2 November 2023

- 3 steps to implement Business Process Automation - 2 November 2023